Custom Sandwich Paper

Design Custom Sandwich PaperGet an Instant Quote

Cost Summary (USD)

No Minimum Order

Free Custom Designing

Best and Competitive Pricing

No Die or Plate Charges

7 Day Turnaround

Free Shipping All Over USA

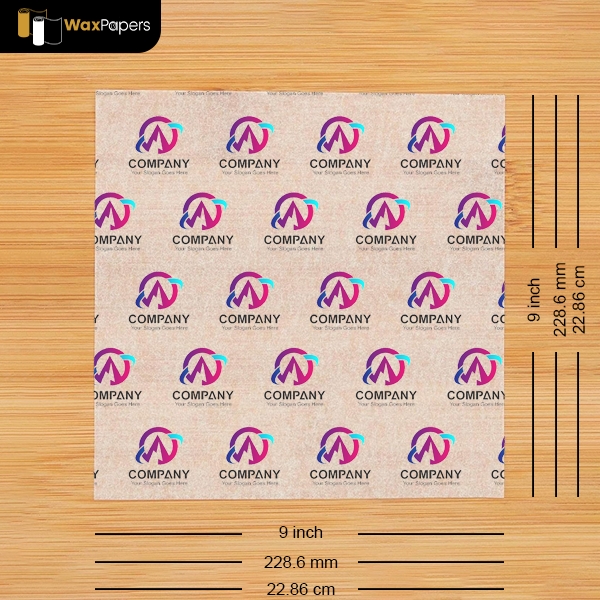

Custom sandwich paper helps you present your food hygienically and professionally. This paper has a food-grade nature that makes it an excellent choice for dairy stores or restaurants. With the printed design on the paper, you can get a remarkable product presentation along with an efficient promotional tool.

Now the market is swamped with food brands. You can even find almost 50 types of sandwiches in the USA alone. This shows that the market is competitive, and you certainly have to do something extra to grab the attention of customers. In this case, custom sandwich wrapping paper is the best option.

At your company, we not only manufacture an ordinary wrap but also help you tell the customers’ stories of your brand by printing the promotional information on the paper. You can get these sheets in any size and in any design, considering the requirements of your product.

Purpose Of Sandwich Paper

The retention of food hygiene is a matter of great concern for food businesses and buyers, and the most effective way to maintain food hygiene is the use of custom sandwich paper. The factors that make the paper’s purpose are as follows:

- Sustainable

- Sturdy

- Cost-effective

- Catchy

- Moisture and tear-resistant

The manufacturing process of Sandwich Paper

Sandwich paper is made from a high-grade manufacturing process, so the finished paper must meet the rigorous requirements. Precise steps are taken at each step, so it should not lack quality in any aspect. From raw material selection to pulping, chemical treatments, and finishing, here are some of the important steps involved in the production of custom sandwich wrap paper:

Pulping

Pulping involves breaking down raw materials into individual fibres. This process incorporates mechanical treatment in which fibres are separated. Different impurities are removed, such as dirt and other contaminants, to improve the strength and flexibility. Here are some of the steps that involve the pulping of sandwich wrap paper custom:

- Raw material preparation

- The raw material is fed into a pulper

- Pulp is passed through screens

- Pulp undergoes a cleaning process like flotation

Bleaching

Bleaching is done after the pulping of sandwich paper to remove natural pigments that can affect the quality of the finished sandwich paper wrap. It helps in improving the strength and printability of paper. Different types of bleaching include chlorine, oxygen, and hydrogen bleaching. The bleaching agent is added to the finished pulp and then left for some time for reaction. The pulp is then again rinsed to remove bleaching agents.

Mixing and forming

Kraft paper is the base material used in the manufacturing of this paper. There are certain steps that we have to follow while manufacturing sandwich sheets. Mixing and forming involves blending pulp with different chemicals and then transferring it to a forming machine to make a paper layer. At the mixing stage, you can get the desired properties, such as water resistance and improved strength. For deli sandwich paper, this is an important step to enhance the strength and increase the longevity of the paper.

Forming helps in achieving uniform thickness and smooth texture of the paper. It can also prevent defects during the pulping process, such as tears or creases. Temperature control is crucial in both stages to optimise the reaction between pulp and chemicals.

Pressing

Pressing involves the use of press rules to apply pressure to the sheets to remove excess water. It results in creating a uniform thickness of the paper and a dried surface, such as smooth or textured. The following are the objectives involved in the process of pressing:

- Remove excess water

- Consistent thickness

- Surface smoothness

Drying

The process of drying helps in removing the dampness of the pressed sheets. It also prevents the shrinking of sheets during handling, storage, and delivery. In drying, the sheet undergoes heating, steaming, or infrared radiation to achieve the desired level of dryness. Moreover, hot air circulation improves sheet stability and prevents wrinkles.

Cutting And Finishing

Cutting and finishing are two final steps that prepare sandwich paper for additional treatments. Cutting involves trimming paper into desired shapes and removing the excess material. It promotes waste minimization and produces clean and smooth edges of the paper. The cutting process involves the following steps:

- Transfer of the sheet to the cutting machine

- Measurement of the sheet to determine the cutting position

- Cutting using a rotating blade or laser cutter

- Edges are trimmed to remove excess materials.

As the name suggests, finishing includes various treatments to make a finished paper. It helps enhance the overall appearance and properties of the paper. Pre-print coatings are applied to smooth the texture and improve the printability process. Say you need sandwich sheets with the absorbent capacity of grease-proof paper, then we have to apply certain sizing agents. On the other hand, if you need a moisture resistance barrier like that of wax paper, then we apply wax coatings and so on. Here are the steps involving finishing:

- Surface treatments with coating

- Paper passed through rollers to improve smoothness

- A design is embossed on the paper surface

- Folds and perforations

Printing Options For Sandwich Paper

We offer high-quality printing techniques, which you can select depending on the number of pages and quality required. We let our clients choose printing techniques within their budget, and every method provides high-quality outcomes. Here are the three most preferred printing techniques used for a unique sandwich wrapping paper design:

- Flexographic printing: Popular option for large-scale commercial use. It produces efficient brand logos, patterns, and text using fine-quality and durable inks.

- Offset printing: Higher printing quality with finer details and intricate designs. It helps in creating a professional look with unique color blends.

- Digital printing: Suitable for short-run printing of paper sheets. Highly customizable and an excellent choice for bands who want to change their design now and then.

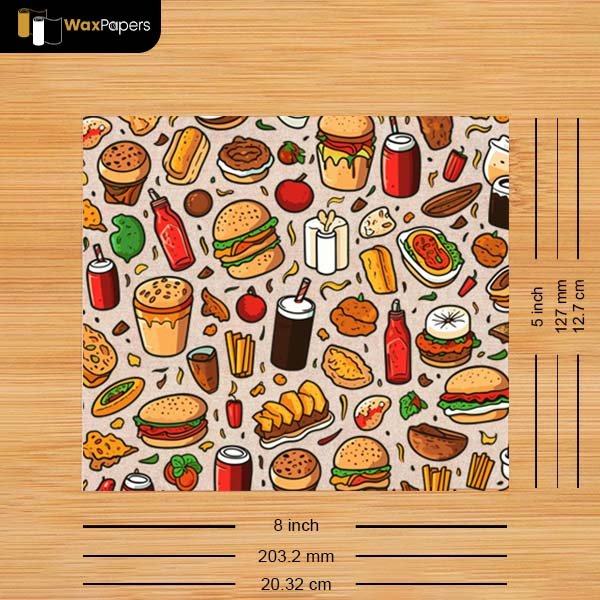

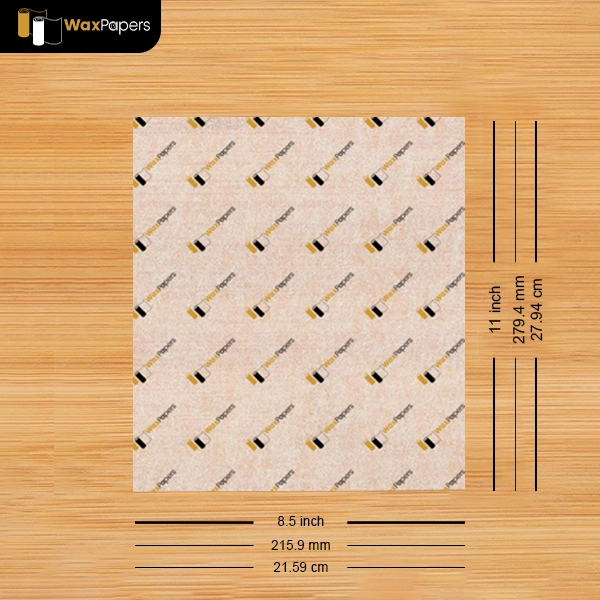

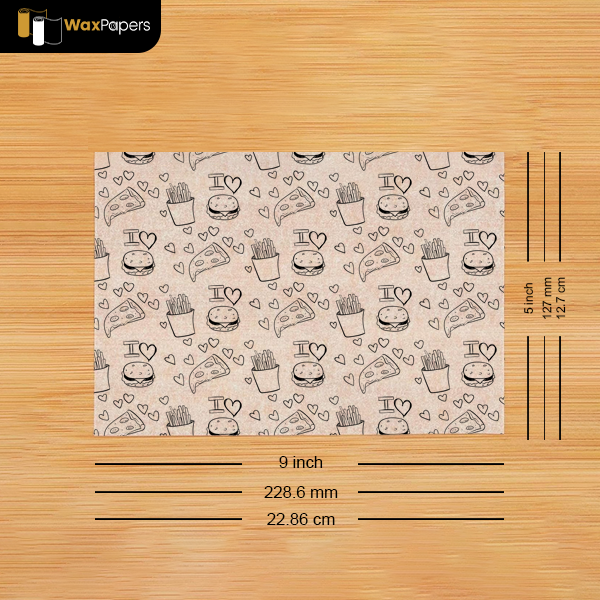

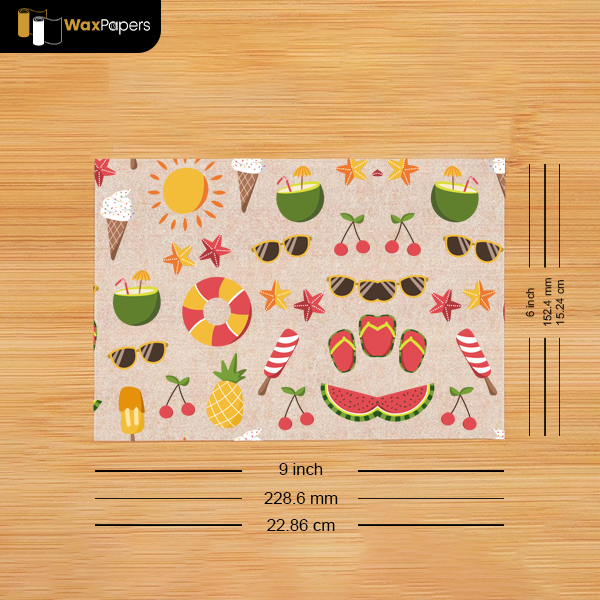

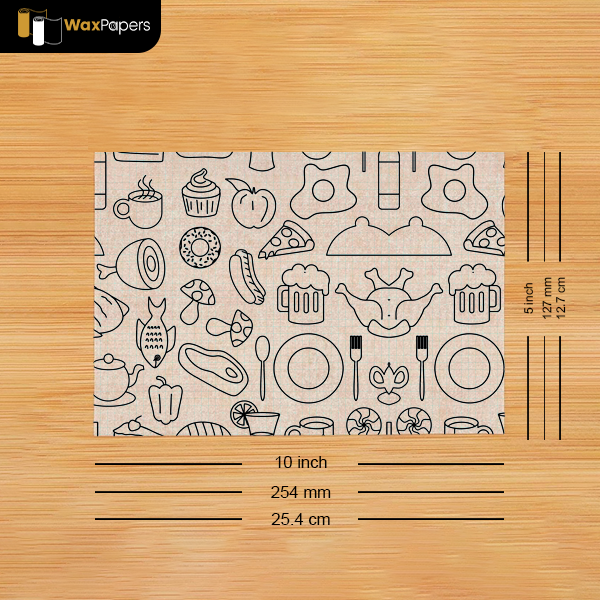

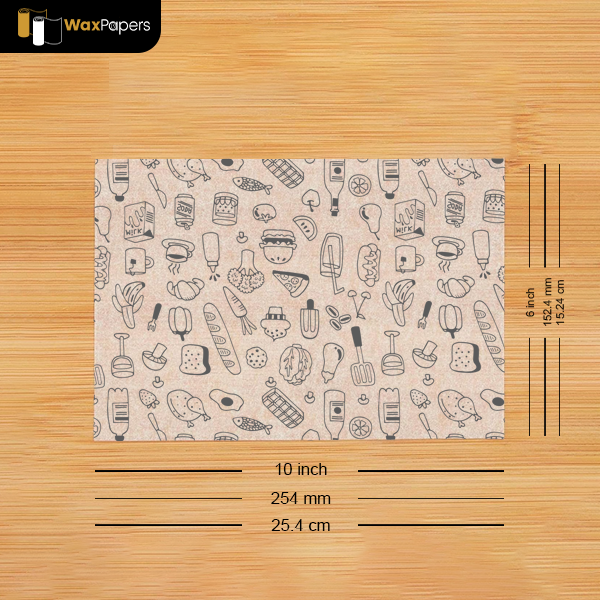

Different Size Options For Various Usage

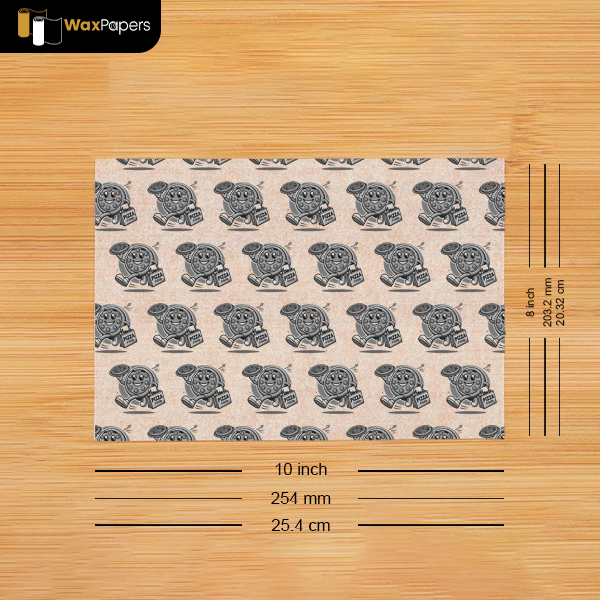

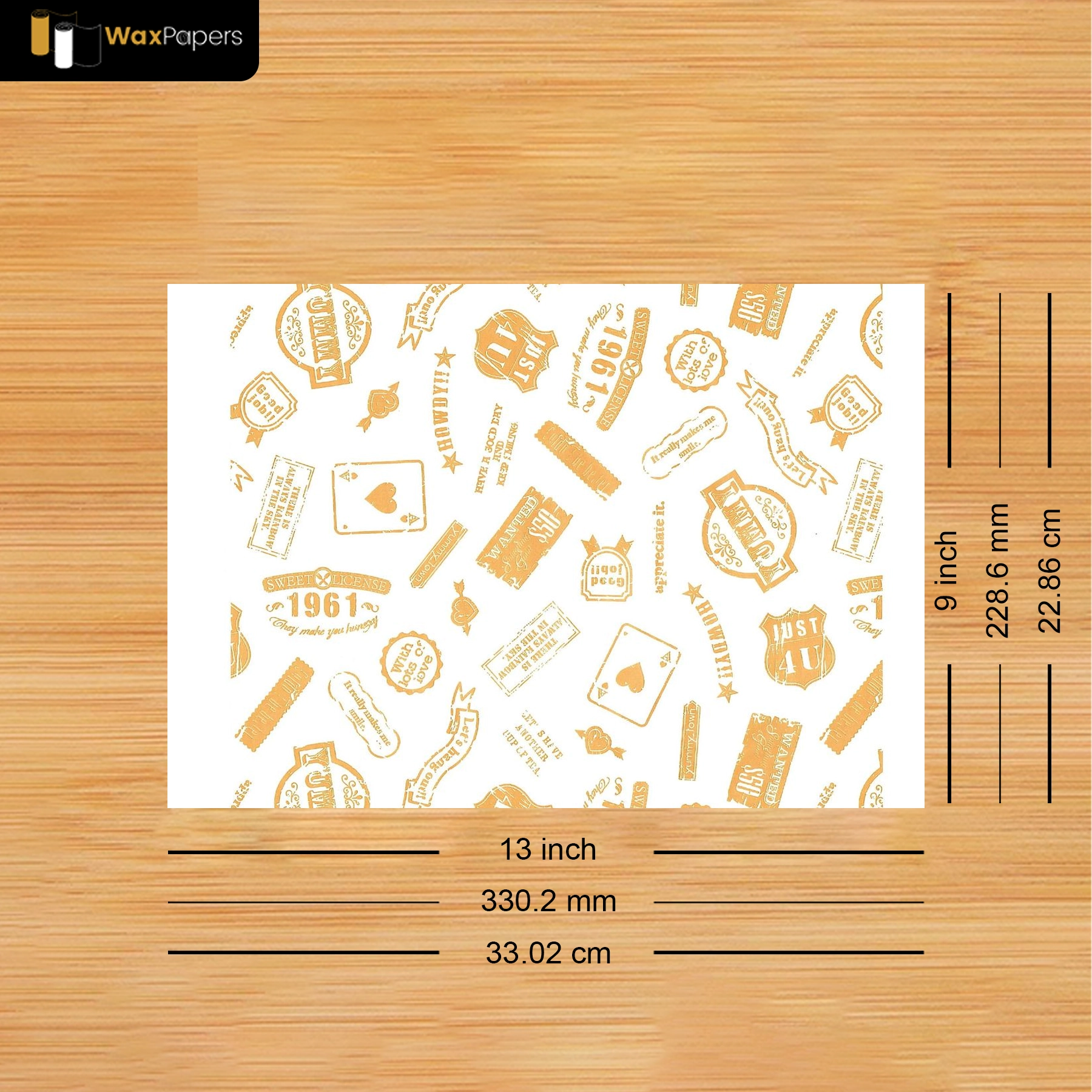

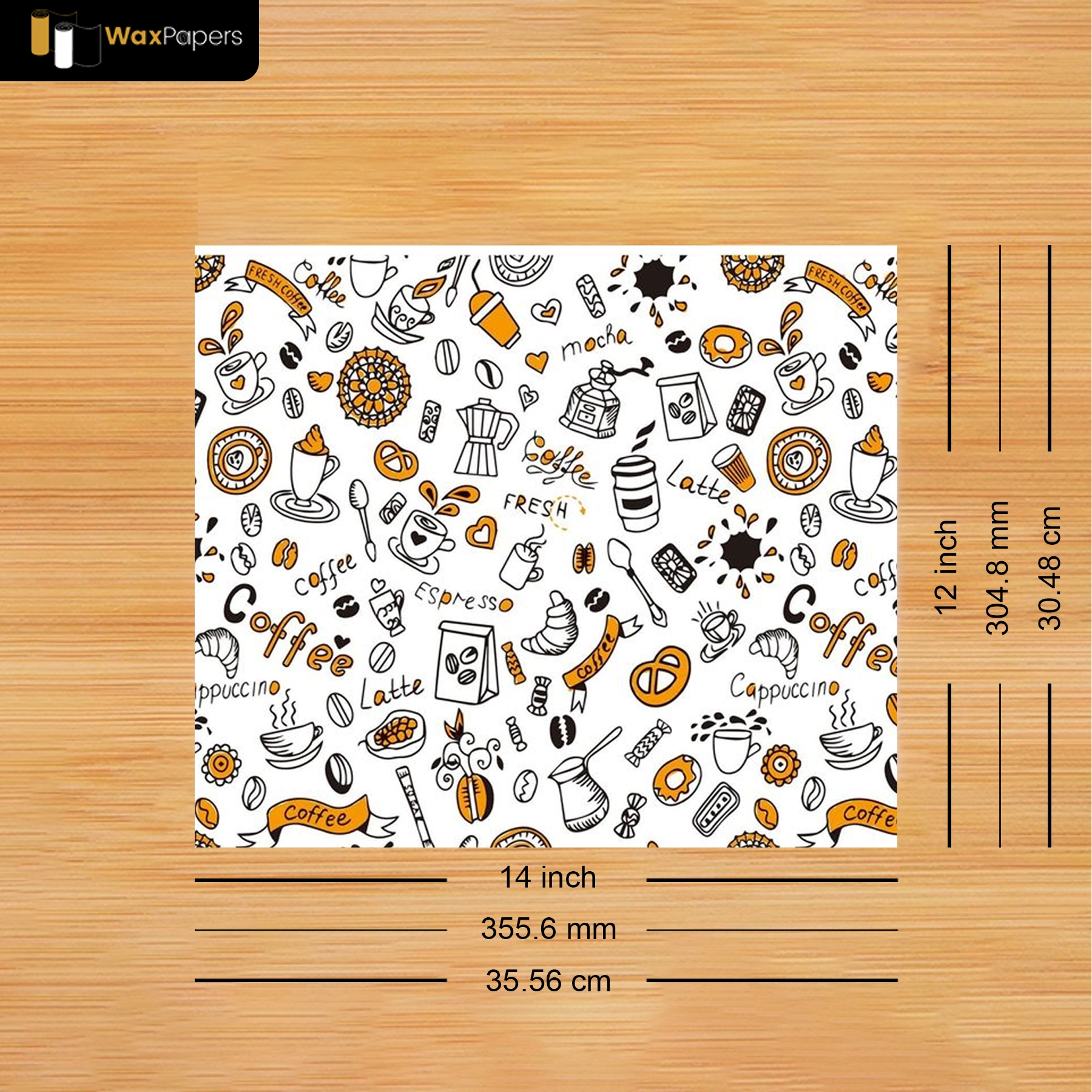

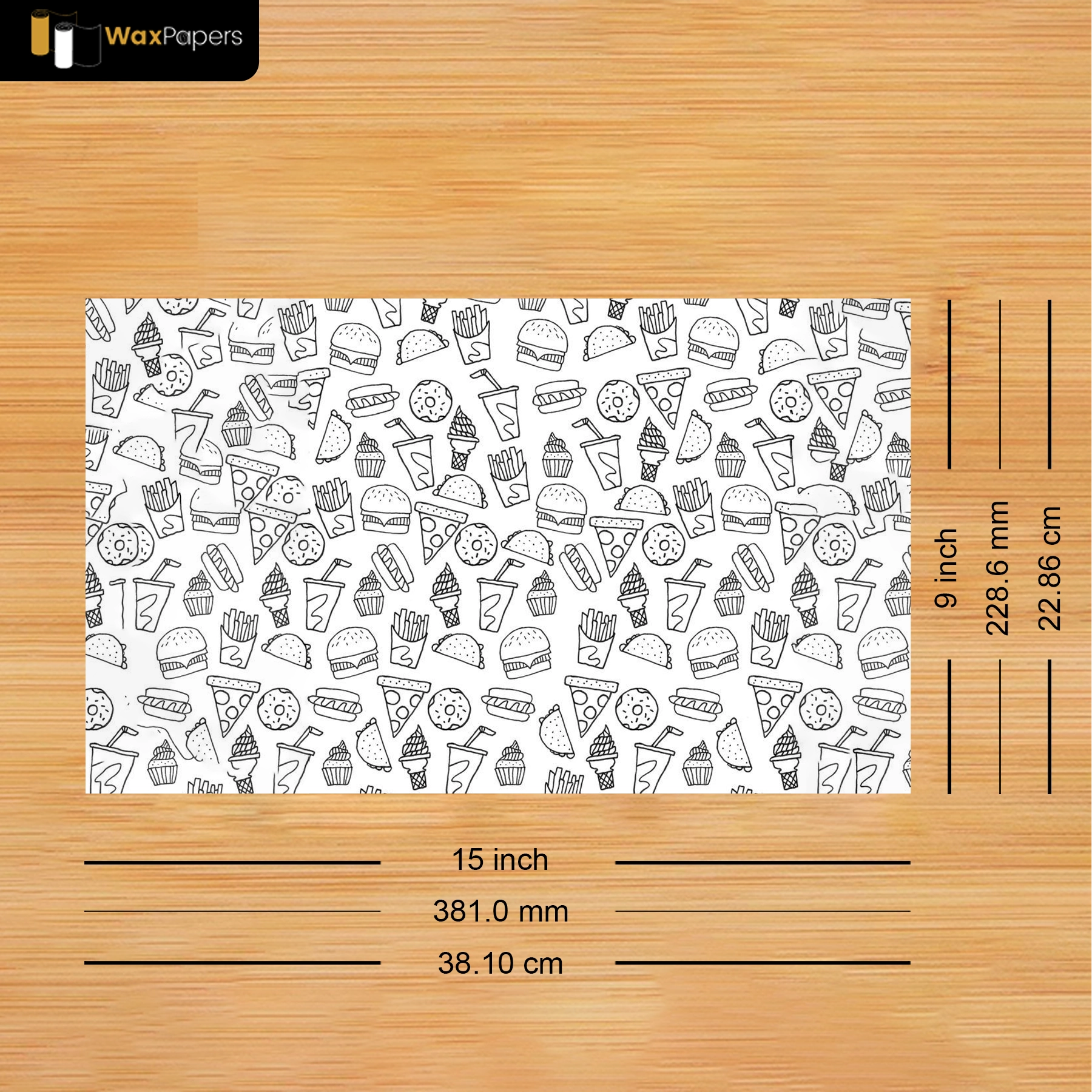

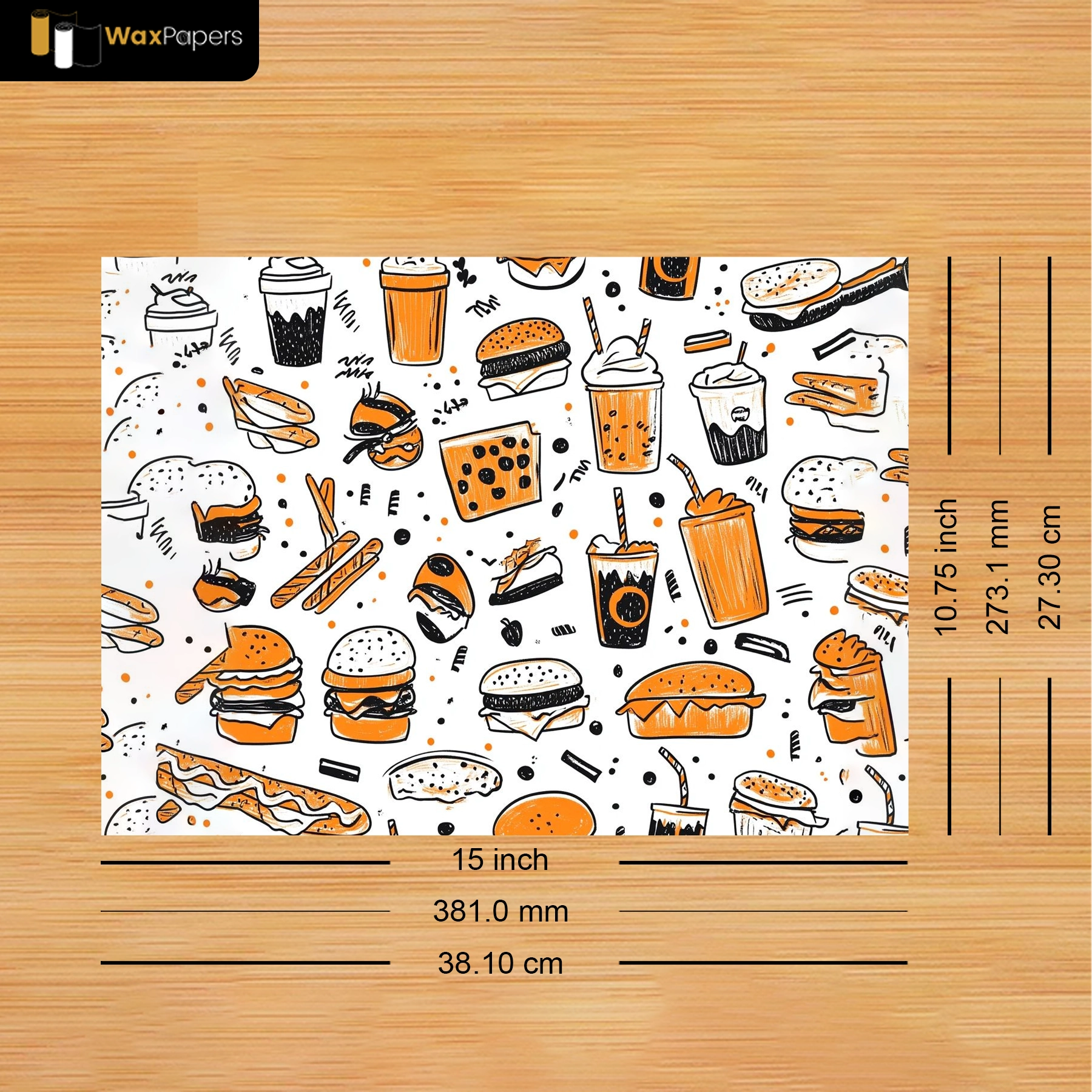

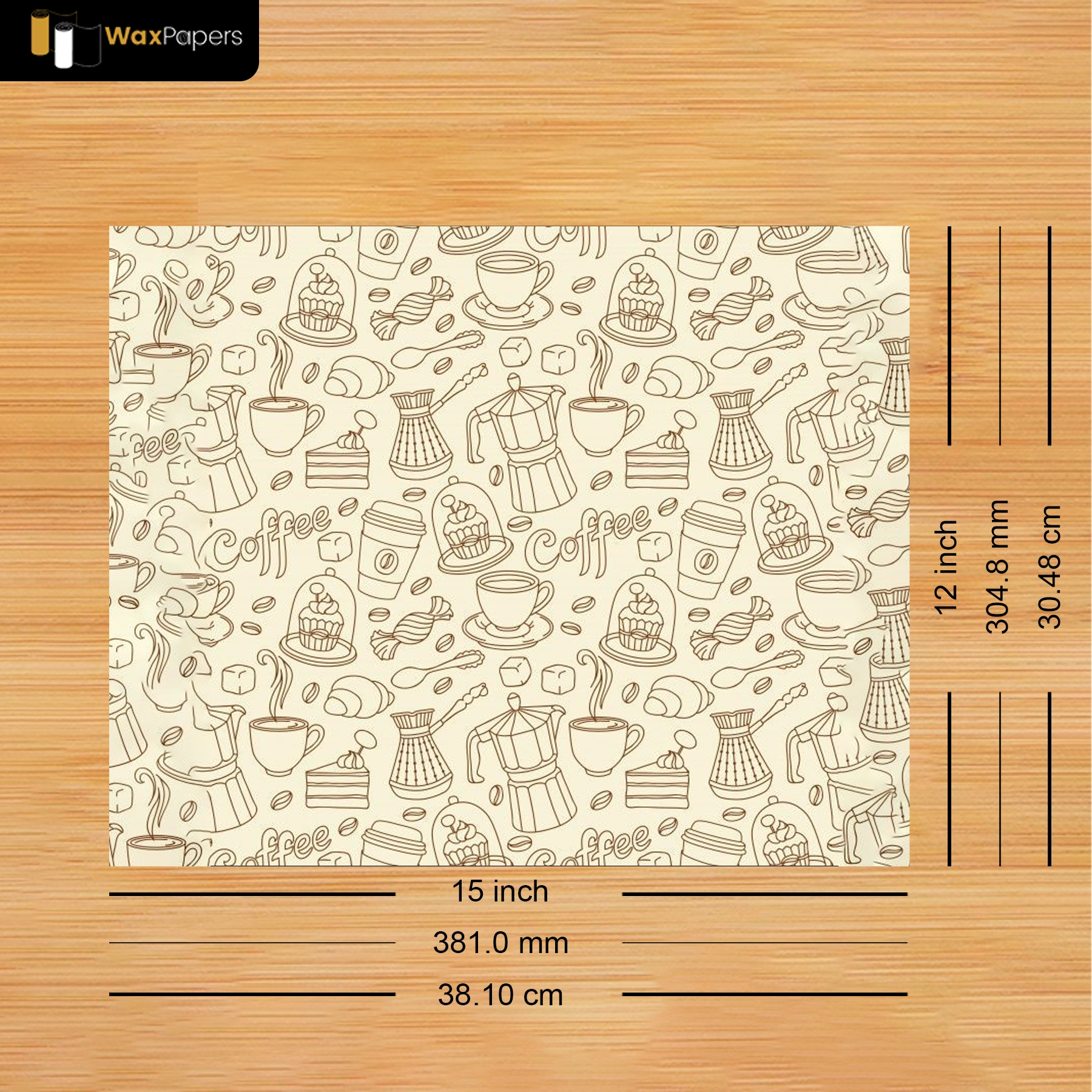

We offer a wide range of custom-size options to fulfil different brand packaging needs or preferences. Our waxed tissue paper has standard sizes that perfectly match different packaging needs, providing a quick product wrapping solution. Moreover, we also offer customized sizes or dimensions options, allowing you to cut the paper to your desired sizes that satisfy all your packaging needs. However, the standard dimensions of the sandwich paper sheets we are offering are:

- 12 x 10.75″

- 12 x 12″

- 12 x 16″

- 12 x 18″

How To Identify Sandwich Paper?

The texture of sandwich paper is bright and crispy, smooth to touch but not slick like plastic-covered papers and wax. It is lightweight and pliable, but rustling slightly as it is held in the hand, a strong indication of how light it is.

Sandwich paper bags and sheets give the slightest resistance that can be felt when you rub them between your hands. Being somewhat porous, it is dry, but not harsh at all. A gentle crumple will make it wrinkle, but won’t be fed into a permanent crease as it will tend to bounce back with a bit of stretch.

When viewed under the light, it is normally transparent. This shows a bit of desertion because it is thin. Ungreased sandwich paper tends to slightly absorb moisture, whereas grease-resistant ones will cause water to roll up into beads.

Certifications Of Food-Grade Nature Of Custom Sandwich Paper Sheets

| Certification | Agency | Purpose |

| FDA Approved | FDA Certified | Food Contact |

| BRC Certified | Global Standard | Safety Compliance |

| FSC Certified | Sustainable Forestry | Paper Sourcing |

| ISO 22000 | International Standard | Food Safety |

| GMP Compliant | Manufacturing Practice | Hygiene Standards |

| Kosher Certified | Religious Compliance | Ingredient Control |

| HACCP Compliant | Risk Analysis | Contamination Prevention |

| USDA Approved | Agriculture Certified | Meat Contact |

| PFAS Free | Chemical Safety | Non-toxic Materials |

| BPA Free | Material Safety | Chemical-Free |

Contact Us!

At waxpapers, we are giving the best and most affordable custom sandwich paper. This paper helps you present your delicious snacks with complete hygiene and remarkable presentation. Call now to get the best rates and free shipping in the USA.

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Product

Dimensions

Frequently Asked Questions

The main purpose of sandwich wrap paper is to provide a convenient and mess-free environment. It is a way to package and consume sandwiches and subs on the go. It helps to prevent grease, oils, and dressings from seeping.

Parchment paper fulfils every requirement, unlike other materials. It absorbs some moisture and has a minor porosity. For further protection, wrap your sandwich in a single sheet, cut it in half through the parchment paper, and then wrap it again.

Yes, we offer free shipping worldwide. We didn’t charge any extra cost to deliver your order at your doorstep.

We do not have a minimum order quantity for custom paper sheets. You can freely order a small unit from us before booking in bulk.

Our entire production facility for custom-printed papers is quick and produces high-quality output. We can finish your order within 6 to 8 business days.

You have to pay 100 % of the fee before the production of the custom paper. Do not worry, all the payment methods are safe and free from any fraudulent activity.

We give a 3D prototype of the paper so that you can see the final appearance of the packaging you are going to receive. You can get as many revisions as you want.

Product

Highlights

Custom Wax Paper

Greaseproof Paper

Welcome to the ultimate destination for Custom Wax Paper and Greaseproof Paper – the perfect way to add a unique touch to your restaurant's food packaging.

Designed specifically for restaurants, our printed paper liners brings unparalleled quality and functionality with a touch of personality to your brand. Enjoy our exclusive offer and order your custom wax paper now!

Get a Quote