Fiber Sorption And Its Impact On Food Paper Absorbency

Custom food paper is frequently used in the wrapping and cooking of food. Some of the papers contain coatings that enhance the functionality and resistance properties of the paper. However, there are many custom papers that are used without any coatings to retain their sustainable aspect and to minimize the use of material.

This feature certainly looks attractive to brands and the buyers who prefer a cleaner environment. Nonetheless, it also raises the question of how that is possible for a paper to be without grease and moisture without tearing? This is due to the phenomenon of “Fiber Sorption,” which is the measure of moisture retention by paper-based materials. So how does that work? Let’s read the blog and understand.

What Is Fiber Sorption?

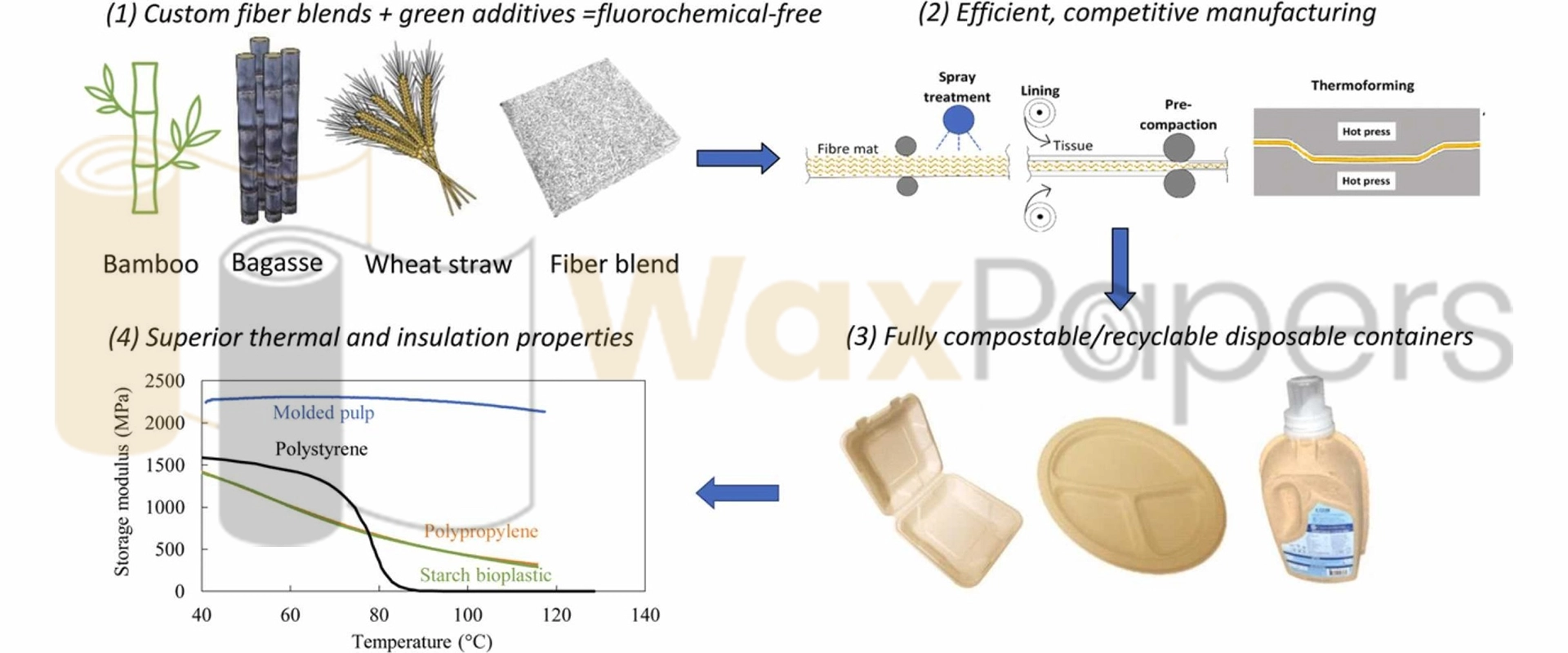

Fiber sorption is a process in which the liquid penetrates paper and is held by the porous network of the paper. It is a barrier property of the paper that affects how it is going to interact with fats or aqueous solutions. The process of sorption occurs due to hydrogen bonding between the hydroxyl group of cellulose and water molecules. The capillary action in pores also sorbs oil due to polar interactions and allows penetration. The sorption kinetics depend on the following factors, too:

- Fiber morphology

- Refining levels

- Surface chemistry

Mechanisms Of Fiber Sorption

Food wrapping papers are manufactured with soft and hardwood fibres. These cellulose fibers contain a large number of hydroxy groups that make hydrogen bonds with water and swell up as moisture diffuses into the fiber wall and lumen.

Moisture Sorption

As we know, materials absorb moisture from the air based on the amount of moisture present. This process is called “isotherm”. As the humidity goes up, the moisture retention also increases. In moisture sorption equilibrium, moisture sorption increases with an increase in relative humidity and influences the mechanical properties of the paper, such as tensile strength and stiffness.

Oil Sorption

Oil sorption in paper is relatively complex due to the viscosity of oil and surface tension. Aside from this, the interaction with the fibre surface also impacts oil sorption. In the greaseproof paper, the absence of pores reduces the absorption. This paper undergoes calendaring and a high refining process that leads to oil sorption in the micro-voids of the fibre, ultimately leading to a reduction in the absorption.

Greaseproof Paper

Custom greaseproof paper is used in the wrapping of food with high fat content to prevent oil penetration. This paper undergoes an extensive refining process to reduce its pores and create a dense sheet that is also called glassine paper. This sheet is then super calendared to enhance its density and further reduce the pores. Sometimes, additional pore size reduction is done by applying substances that fill the pores and impart oil repellency. such as:

- Starches

- Alginates

- Carboxymethy cellulose

Fiber support is one of the most important features of grease-resistant paper that ensures the absorption of oils into the fiber network rather than into the large surface pores. The highly beaten paper has a significant swelling potential that allows the stored oils to remain within the fiber wall to prevent staining and seepage.

Fry Paper

Custom fry paper is a type of grease-resistant sheet that is manufactured for high-temperature frying applications. This paper also has oil resistance and high-end heat resistance that allow it to stand the heat emanating from the deep-fried food. Aside from the enhancement of oil resistance properties at the time of manufacturing, we apply silicone coating on the paper to make it highly durable and heat resistant.

Fry paper can be used for oily food serving without the application of a coating. Nonetheless, the application of silicone coating reduces the hydrophilicity and creates a non-porous surface that prevents oil sorption even in the fiber matrix at the typical frying temperatures.

Butcher Paper

Butcher paper is also an uncoated option that is lightweight and is used to wrap meat and other deli items for moisture management and breathability. Unlike grease and fry paper, this retains porosity to wick surface fluids away from the meat item. This is necessary to prevent sogginess and bacterial growth in meat.

Butcher paper sheets have a unique ability to absorb exudates from tissue via capillary action into its loosely bound fibers. This draws fluids away from the product’s surface and reduces the mess. In this paper the absorbance depends upon the hydroxyl rich structure of cellulose fiber that forms hydrogen bonds with water and aqueous meat fluids which ultimately enhances the sorption capacity of the paper.

To prevent the excessive leakage while preventing the breathability of butcher sheets, it is treated with starch-based sizing that makes the absorbance capacity moderate without creating a continuous hydrophobic film. Sometimes a thin layer of wax can also be applied that gives wax paper like properties and reduces breathability.

Kraft Paper

Custom kraft paper is produced via an alkalization process that gives a strong paper sheet. This process is also known as the Kraft process, which gives a moderate level of porosity and barrier properties to the paper and sorption characteristics. These features make Kraft wrapping paper a good option for products that need a moderate amount of moisture and oil management.

Its moisture absorbance properties also rely on relative humidity and increase with an increase in the surrounding moisture. To enhance the barrier properties of the paper, its surface is sometimes impregnated with cassava starch acetate that significantly reduces the water vapor permeability and degrees of hygroscopicity.

Sometimes chemical modifications, such as glyoxal crosslinking and polymer grafting, can also be done that reduce the hygroscopy and improve the dimensional stability of the paper.

Conclusion

The absorptive ability of custom food paper depends largely on the fiber sorption, and this depends upon the fiber refining and the density of the paper. With the use of different chemicals or with the application of coatings, the surface properties of the paper are changed, and hence the absorptive properties. The better the refining process, the better the moisture and oil barrier properties of the paper are. At Waxpaper, we use advanced manufacturing facilities that give refined and dense sheets of paper to help you pack your product effectively.

Beta feature

Beta feature