Custom Greaseproof Paper

Design Custom Greaseproof PaperGet an Instant Quote

Cost Summary (USD)

No Minimum Order

Free Custom Designing

Best and Competitive Pricing

No Die or Plate Charges

7 Day Turnaround

Free Shipping All Over USA

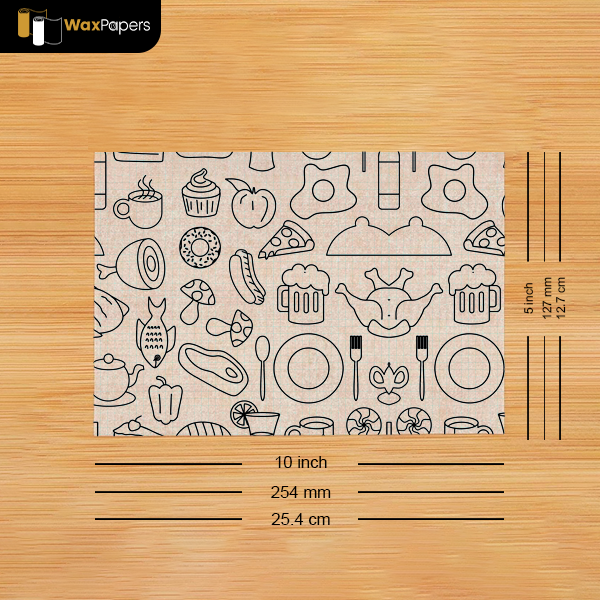

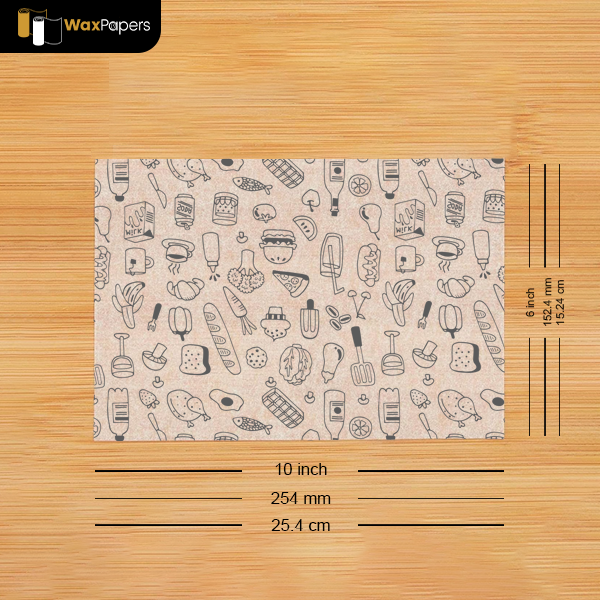

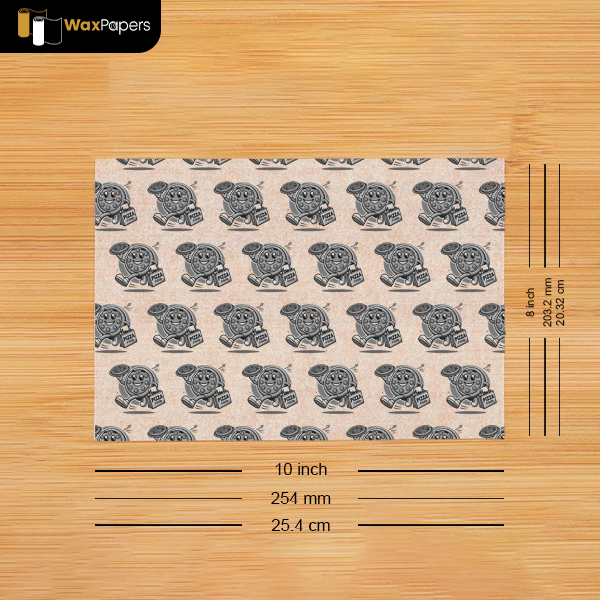

Custom greaseproof paper is a special wrapping paper that is used to resist oils and grease without the use of wax or any coating. This paper is widely used in the fast food industry and in bakeries because of its non-sticky nature and translucent appearance.

The resistance of grease-resistant paper sheets is enhanced by treating the raw material with certain chemicals and processing it via certain manufacturing processes. Advanced mechanical refining and internal sizing make it an eco-friendly, sturdy food wrapping paper.

Using greaseproof paper sheets printed with the logo of your company, you can use them as a remarkable and excellent tool to promote your brand. In addition to this, we give professional and wholesale manufacturing services that help you get the premium quality wrap without breaking the bank.

What Material Is Used To Manufacture Greaseproof Paper?

The primary material used in the manufacturing of grease-resistant sheets is virgin pulp. This pulp is derived from the combination of soft and hardwood fibers. We prefer FSC-approved forests to prevent uncontrolled deforestation and ensure the purity of the raw material. The following steps are involved in manufacturing greaseproof paper sheets:

Virgin Cellulose Pulp

We use 100% virgin pulp to ensure that there is no residual contamination in the raw material. The pulp has two different types of fibers: long and short, which contribute to the strength and flexibility of the packaging paper. The fibers obtained from soft food give durability to the paper, while those obtained from hardwood give a smooth surface.

Bleached And Refined

The raw pulp has a brownish color, just like Kraft paper. To remove this color, we have to treat the raw material with bleaching agents that remove impurities and lignin to give you a clean and food-grade material. This also enhances the paper’s appearance and removes any odor present in the pulp so that you can use it directly to wrap your edible products.

Fiber Uniformity

Bleaching gives refined fibers that are distributed evenly to manufacture uniform sheets. This is a crucial step where a dense and tight fiber matrix is produced through various steps, including the use of mechanical refiners. Friction and pressure are applied to the paper, which gives:

- Fibrillate the fiber surface

- Cut overly long fibers

- Soften and swell the fiber

The result of these steps is pulp having similar strength and flexibility, along with a bonding surface.

Controlling Consistency

We have to dilute with a specific concentration of water to fiber ratio. This is done to control the concentration of the pulp. Via this method, fibers will be distributed evenly, and no clumping of the raw material will occur, which may leave gaps.

Screening And Cleaning

To ensure an impeccable quality of the paper, we screen the pulp to remove any oversized fibers and debris. Pressure machines and centrifugal cleaners are used to get a uniform and clean batch of pulp.

What Is The Manufacturing Process Of Greaseproof Paper?

The manufacturing process of grease-ressite paper sheets is a multi-step process. Here, the wood pulp is converted into a smooth and grease-resistant sheet via several interconnected and controlled steps. The main purpose of these steps is to give the plan sheet the following features:

- Ehace fiber bonding

- Reducing porosity

- Keeping the paper foot safe

Pulp Preparation

Wood is debarked and cooked with chemicals such as sodium hydroxide and sodium sulphide in a digester. This separates the lignin from cellulose. After this, the pulp is washed off and bleached to create pure and food-grade material.

Beating And Refining

The bleached pulp is mechanically beaten into fibrillar fibers. These steps convert the fibers into microfibers, creating a jelly-like slurry that has high bonding capacity, resulting in low porosity and increased resistance to grease.

Sheet Formation

After refining, we dilute the pulp and pour it over the Fourdrinier wire mesh to form a thin and wet sheet of paper. Water is drained to uniformly distribute the fibers, which ensures a grade-proof appearance with consistent quality.

Pressing And Drying

As we have to give a flat and smooth surface to the paper, we pass the sheets through heated drying cylinders. This process locks fibers in place and solidifies the sheet structure.

Supercalendering

After the paper is dried in heated cylinders, it is passed again through the polished heated rollers or cylinders. The surface of the paper is compressed to remove micro gaps and give grease-resistant sheets a smooth and glossy surface. After this process, the paper is cut into sheets and dispatched.

What Additives Are Used in Greaseproof Paper?

As we know, greaseproof paper sheets do not have this kind of coating, which is why the paper is treated with certain additives to enhance its properties. A balanced ratio of internal sizing agents and strengtheners is added to enhance surface and performance.

Internal Sizing Agents

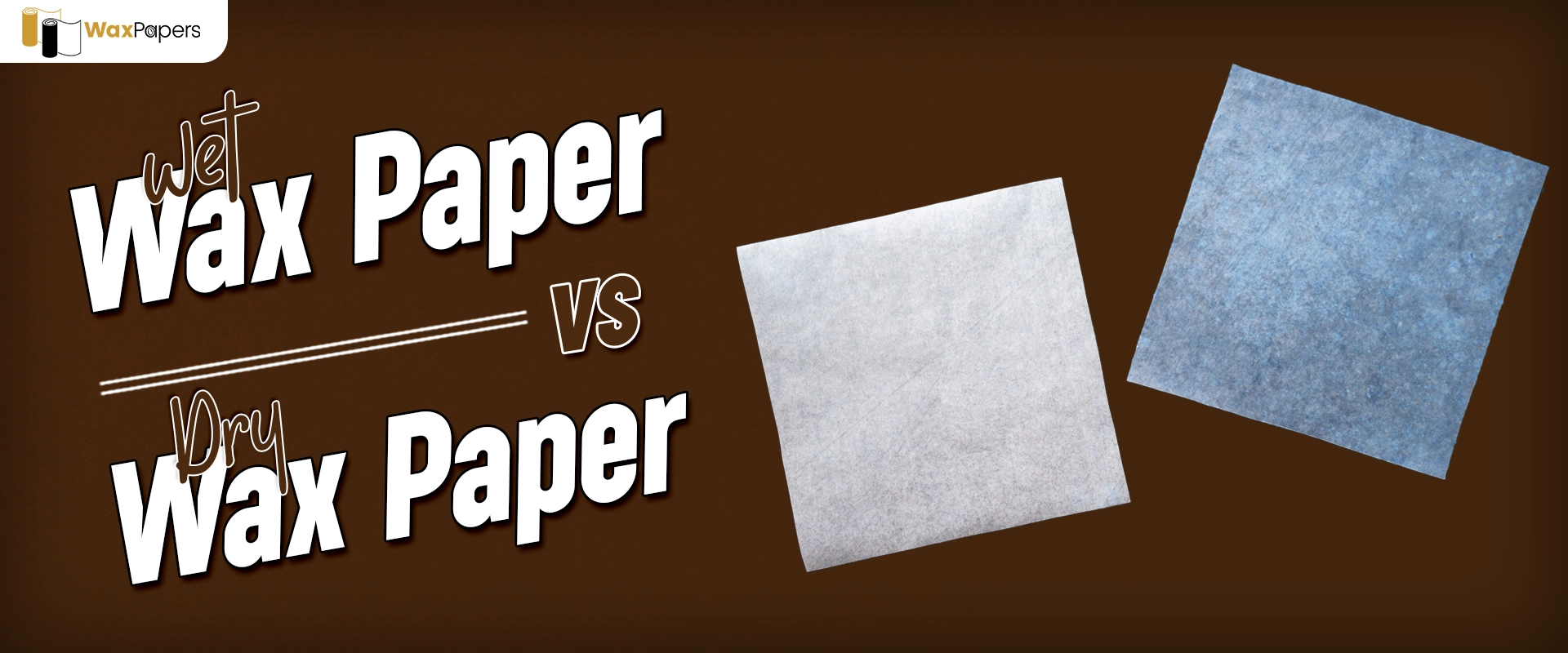

Internal sizing agents are added at the time of pulp creation to give internal hydrophobic barriers that block grease and oil from seeping through the paper. This enhances the grease-resisting properties of the paper more than those of custom wax paper.

Modified Starches

Modified starches are derived from natural resources such as corn and potatoes. These starches bind the fibers to reduce water and oil absorption.

Alkyl Ketene Dimer (AKD)

Alkyl ketene dimer is a synthetic sizing agent that binds with the fiber chemically. It also enhances the grease and moisture resistance from the inside out.

Surface Strengthening Agents

Surface sizing agents improve the durability and printability of the paper by reinforcing the fiber network.

Cationic Starch

Positively charged starch increases the surface and fiber bonding of the paper. This prevents the fiber linting and enhances the surface smoothness for printing.

Wet Strength Resins

Wet strength recommendations are used to ensure the functionality of paper sheets in a hot and moist environment. These resins maintain the integrity of the paper when you wrap wet or most food in them. Certainly, it does not act as PE-coated freezer paper, but it is a good option for moist meals.

Polyamide Epichlorohydrin (PAE)

It forms a strong cross-link structure of cellulose fibers and improves the tear resistance of the grease-resistant food paper when you tap humid and steamy food items.

Fillers

Fillers are used in a minimal amount to improve the opacity and appearance of custom-printed greaseproof paper. Aside from this, it increases the grease resistance capacity as well. There are two types of fillers that are commonly used:

- Titanium Dioxide is used to enhance the brightness of paper

- Clay improves the smoothness and printability of paper, but it is added in a very small concentration as it can change the density of the paper.

How Is Greaseproof Paper Resistant To Grease Without Coating?

In greaseproof paper, the resistant properties are not due to the application of a coating, but due to the dense fiber structure that this paper has. The pulp undergoes intensive beating, which breaks down the fibers into microfibers. These microfibers form tight hydrogen bonds, which reduce the natural porosity of the paper and leave no room for grease.

Supercalendring compresses the sheet and polishes the surface to close micro pores. Unlike wax and parchment paper, this paper does not need wax or silicone coating. In this paper, the barrier is internal, which makes it breathable and compostable.

How To Identify Greaseproof Paper By Touch And Feel?

- Smoothness: It has a sleek and polished surface, with a slippery surface

- Stiffness: slightly rigid

- Glossy Finish: Light sheen due to super calendaring

- Sound: When you rub it, it produces a squeaky sound

- Grease Test: If you drop oil, it remains on the surface

- Transparency: It holds against light and has a semi-transparent surface due to refined fibers

Contact Now!

Get custom printed greaseproof paper and wrap your food items in premium-quality material with perfect presentation. Wax Paper is giving you the most affordable rates in the USA for all the food packaging, along with unlimited customization options. So, contact us at ASPA.

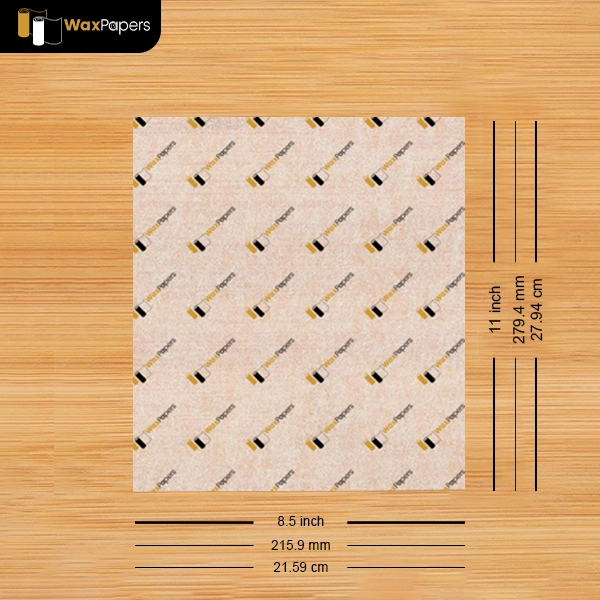

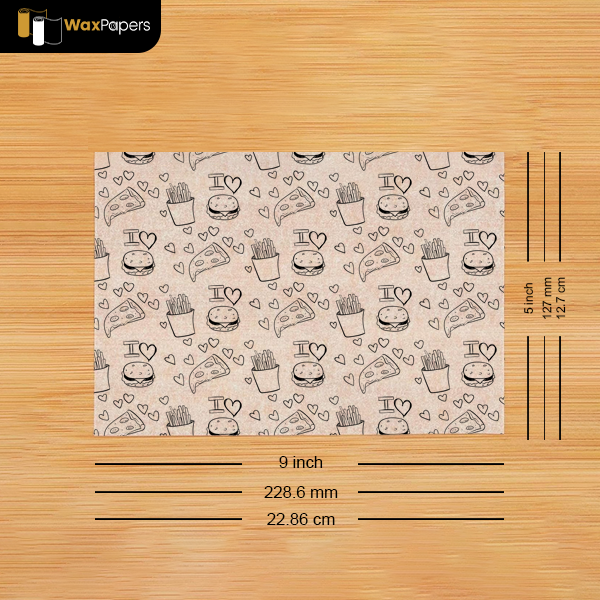

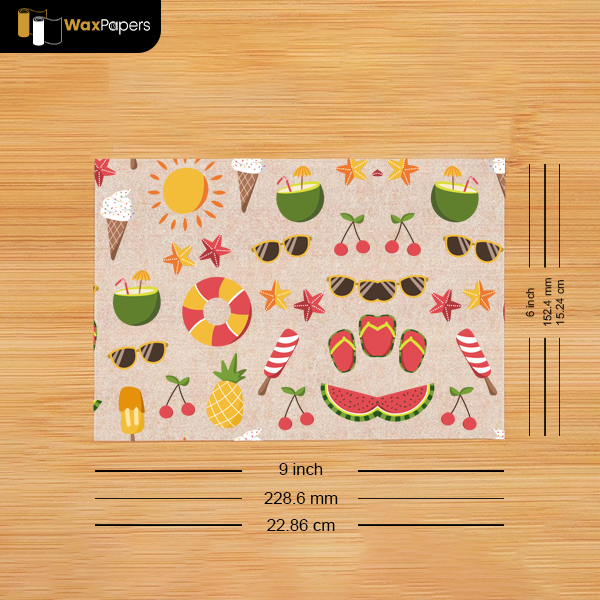

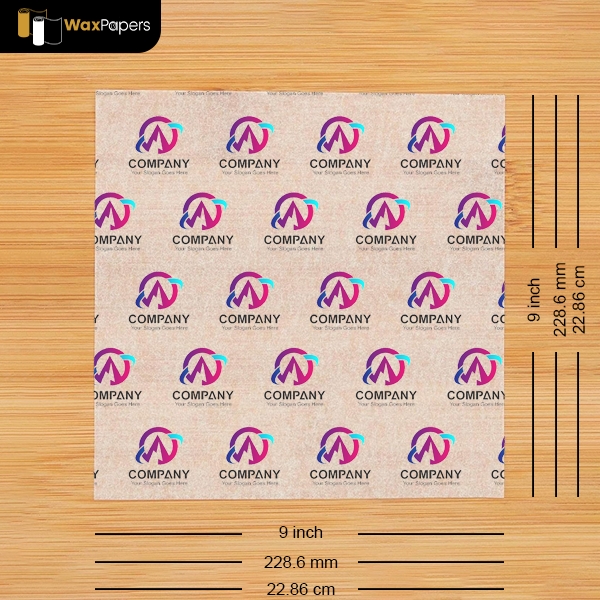

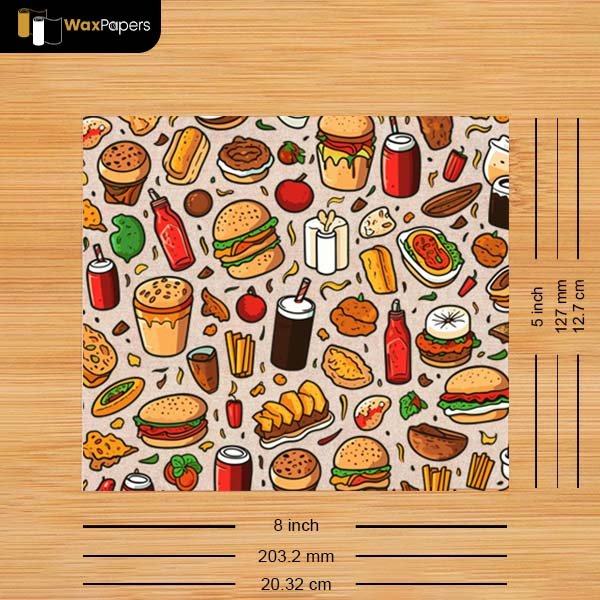

Dimensions

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Product

Dimensions

Frequently Asked Questions

You can have any of your required sizes because there isn’t any specific size we are stuck with, so you can have any according to your product and business needs.

Yes, it is safe to use for microwave use. You can have any of your required sizes and the rest of the things accordingly.

Yes, grease-proof paper is totally fine for freezer use where you can have your meat or any of the other products get frozen without even getting stuck with the surface.

Yes, we are offering good discounts for bulk orders and that’s how we will let you get the best at a very reasonable rate. So you can manage the rest of it for your business growth.

You just need to come in contact with our experts. They will let you get all of the aspects of your wax paper customized according to your brands.

Product

Highlights

Custom Wax Paper

Greaseproof Paper

Welcome to the ultimate destination for Custom Wax Paper and Greaseproof Paper – the perfect way to add a unique touch to your restaurant's food packaging.

Designed specifically for restaurants, our printed paper liners brings unparalleled quality and functionality with a touch of personality to your brand. Enjoy our exclusive offer and order your custom wax paper now!

Get a Quote