Custom Glassine Paper

Design Custom Glassine PaperGet an Instant Quote

Cost Summary (USD)

No Minimum Order

Free Custom Designing

Best and Competitive Pricing

No Die or Plate Charges

7 Day Turnaround

Free Shipping All Over USA

Glassine paper is considered the unsung hero when it comes to specialty packaging. Whether you want to preserve the delicate stamps or wrap gourmet treats, the sleek and unique appearance of the paper sets it apart. When presentation and performance are both required, this paper is the best option.

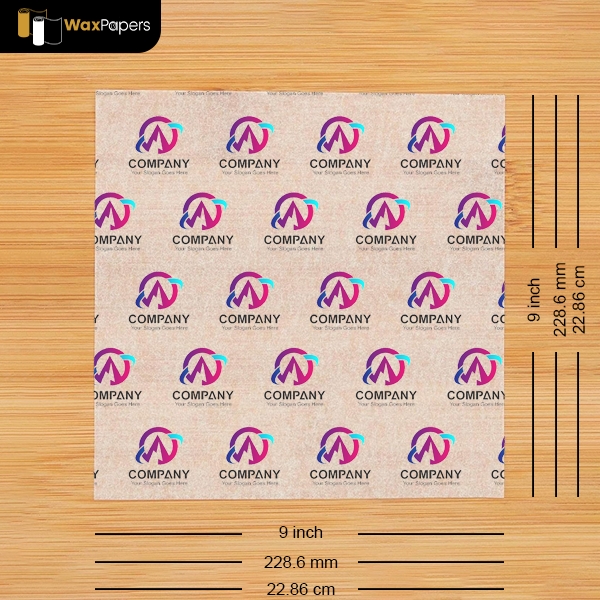

In the market, you can find a huge variety of paper to meet the requirements of your product. From glassine paper bags to plain sheets, this paper is available in several forms. The printed artwork on the paper plays a significant role to grab the attention of customers and help brands to promote themselves.

What Is Glassine Paper?

It is a smooth and glossy paper that has a semi-transparent appearance. The unique surface and smoothness of the paper are due to a process known as supercalendering that compresses the fibers and creates a dense sheet of paper with a uniform surface. This custom food wrapping paper is:

- Air-tight

- Non-porous

- Grease-resistant

- Thin yet durable

Glassine paper rolls have amazing characteristics, some of which are elaborated below:

Translucency

Glassien has a see-through quality that comes from the dense fibre structure and the absence of chemicals. The semi-transparent nature is a perfect option for showing off a product subtly. For instance, you can cover the bakery cookie with this paper that will be slightly peeking through the glassine sheet. It is naturally clear and is distinct from coated or synthetic transparent sheets.

Grease-Resistance

Glassine paper bags or sheets are non-porous due to tightly packed fibres. That is why it can naturally resist oils and greases without the application of any plastic or chemical treatment. For a clean and crisp presentation, you can use this paper and prevent oil stains and seepage.

Smooth Texture

The process of supercalendring involves pressing the paper to hot rollers that create an ultr-smooth surface. This gives a sleek and waxy texture to the paper. Glassine has almost the same smoothness as that of wax paper, but the former is without any coating. This offers a premium feel and a luxury branding option with high-end precision in protection.

Non-Static And Dust-Free

Plastic and regular paper can attract dust. However, glassine sheets are anti-static and repel these particles. That is why this paper is ideal for archival and medical usages where cleanliness is crucial. This paper does not hold or cling to static charge and offers a protective condition that protects the packed documents.

pH Neutral And Acid-Free

As glassine paper sheets have a neutral pH, they can be used to pack documents. This feature of the paper prevents discoloration of the documents and can be trusted for storing artwork and stamps. The stable pH preserves the documents without the use of any kind of chemical treatment.

Environmentally Friendly

The paper is 100 % sustainable because it is not coated with anything. To retain the sustainable structure of the wood, we do not use any chemicals at the time of manufacturing. So if you are looking for sustainable packaging without sacrificing quality, then custom glassine paper is an ideal choice.

Manufacturing Process And Technical Aspects of Glassine Paper

In the manufacturing of glassine sheets, we have to follow a precision-driven process that consists of several stages. These steps are essential to give the paper its smooth surface and translucency. In addition to this, the uncoated grease-resistant feature is also attributed to the manufacturing process.

Refining High-Grade Wood Pulp

The process of refining begins with high-quality wood pulp that is derived from hard and softwoods. This pulp is mechanically and chemically refined and ground into a fine slurry. The purpose of this step is to shorten and fibrillate the cellulose fibre and increase the surface area and bonding capacity. By this, we get a uniform and short fibre structure that bonds together firmly.

Beating and Hydration

This step involves the intense beating of the fibre, followed by hydration. Here, the fibres are further broken down and mixed with water. The result is that the fibre swells and develops fibrils that are tiny, hair-like structures. Tight inter-fibre binding and a dense structure of the sheet are formed. This process is quite critical in giving the paper low porosity and a non-absorbent structure.

Sheet Formation

A Fourdrinier paper machine is the area where the pulp is spread and converted into thin sheets. Gravity and vacuum suction are used to remove the excess water as the wet web moves along the mesh belt. The result of this process is a thin white sheet that has a small amount of moisture, but which has already formed.

Drying Stage

Glassine paper rolls or sheets are passed over steam-heated drying cylinders. These machines remove excessive moisture without disturbing the structure of the web. Precise temperature and pressure ensure the paper dries quickly and evenly, so that dimensional stability can be achieved. The result of the drying process is a dry but non-calendered sheet that is neither smooth nor translucent.

Supercalendering

The regular kraft paper is converted into a glassine sheet via the Thai process. Paper sheets are passed through hard steel and soft cotton rollers alternatively under high heat and intense pressure. In this process, the following things happen:

- Fibers are flattened and aligned

- Air pockets are removed

- The sheet becomes extremely dense and smooth.

- Light is able to partially pass through it, creating translucency.

- The paper acquires its signature glossy and slippery finish.

How To Identify Glassine By Touch And Feel

Glassien paper sheets are different in texture from other custom papers. By touching, you will feel a smooth and slick texture that has a slight transparency. The paper feels dry, and when you rub it, it feels smooth, unlike uncoated butcher paper. A quality customized glassine sheet glides easily and has no rough fibrous surface.

Printing On Glassine

For custom printed glassine paper, we specialize in inks because it has a non-absorbent surface. The slick surface of the paper does not allow the ink to penetrate, which is why we have to use the following printing options:

- Flexographic Printing: This is suitable due to its fast drying and low viscosity inks.

- UV Offset Printing: In it ink is cured with UV light without the requirement of ink absorption.

- Screen Printing: This method is used for short runs and bold methods.

When it comes to printing on glassine, we have to make sure that the inks are UV curable and quick drying. Adhesion of the ink can be challenging, which is why the surface is treated with options such as corona discharge. Other than this, pre-coatings can also be used that will allow us to print the paper flawlessly.

Oven And Freezer Suitability Of Glassine Paper

| Glassine Paper In Oven | Glassine Paper In the Freezer |

| Glassine paper is not suitable for high heat temperatures in an oven. This is resistant to grease and moisture. But, you can use parchment paper in the oven for cooking and baking. | Glassine sheets can be used in the freezer due to their moisture and grease-resistant properties. You can wrap your meats, vegetables, and other frozen items. It prevents freezer burns and maintains the taste of foods. |

Applications of Glassine Paper

The main purpose of glassine wrapping paper is food wrapping. It can be used for various non-food applications too. Some of the common applications of glassine wraps are as follows:

Stamp And Collectibles Storage

Glassine paper bags or envelopes are an ideal option to pack staples and art. This is because the papers are acid-free and non-abrasive, which keeps moisture at bay from the documents. Glassine neither reacts with the paper chemically nor does it stick to them, and ensures a safe archival for long periods.

Food Wrapping And Bakery Packaging

This is the common application of paper, as it is grease-resistant and keeps baked goods such as cookies and sandwiches fresh and appealing. Personally designed glassine does not impart taste or odour to the paper and maintains the product integrity for artisanal or retail food businesses.

Seed And Agricultural Packaging

The moisture barrier property of the paper makes it ideal to wrap seeds and protect them from humidity. You can also see through it to check seed quality due to its transparency. It is biodegradable and is perfect for agricultural sample packaging that demands both preservation and sustainability.

Release Liners In Labels Or Stickers

Glassine is a common paper for stickers and labels. The ultra-smooth surface of the paper makes sure that it is easy to peel and does not tear or leave residue while you remove it from the labels. Thai features are quite essential in the printing and packaging industries.

Cosmetic And Pharmaceutical Packaging

The paper offers a clean and inert barrier that does not interact with the sensitive formulations. You can use glassine as an alternative to a basket liner in soaps and skincare products. Thai will ensure safety and upscale visual appeal.

Luxury And Eco Packaging Inserts

A custom-printed glassine wrapping paper can be used as an insert in jewellery and garments to protect them from oxidation. In chocolates, you can use the paper in place of padded inserts if you just have to keep the layers of chocolate separate. By this, you will be able to give a tactile experience to the customers and keep the product presentable without the use of unsuitable plastic.

Coating And Glassine Paper

Typically, no coating is applied to glassine sheets. The natural grease-resistance of the paper is sufficient to wrap greasy foods. The addition of coatings will interfere with the recyclability of paper and reduce the archival safety. In certain industries, a slight coating is applied to make the release easy, such as in release liners.

Contact Us!

Get custom printed glassine paper wrap made with food-safe and durable material. 100% five sustainable and easy to use, our custom paper is the perfect option for multiple industries. Call waxpapers and get the most premium packaging experience at affordable rates.

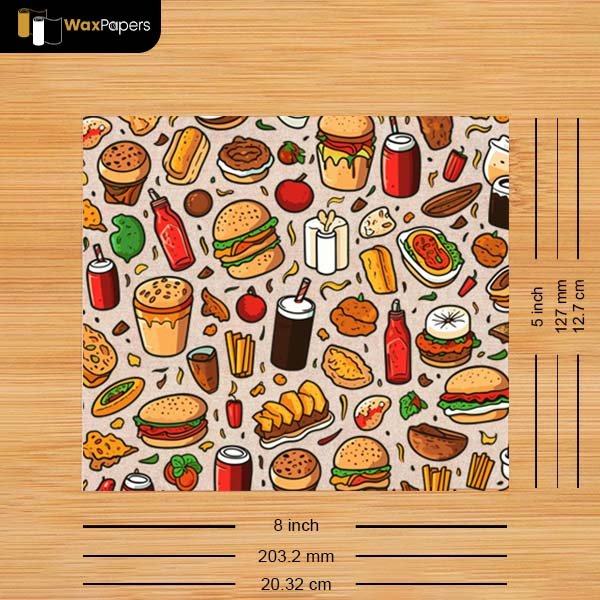

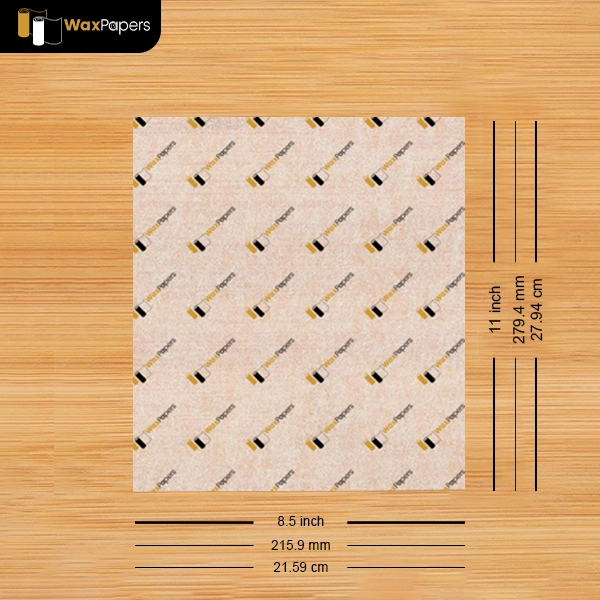

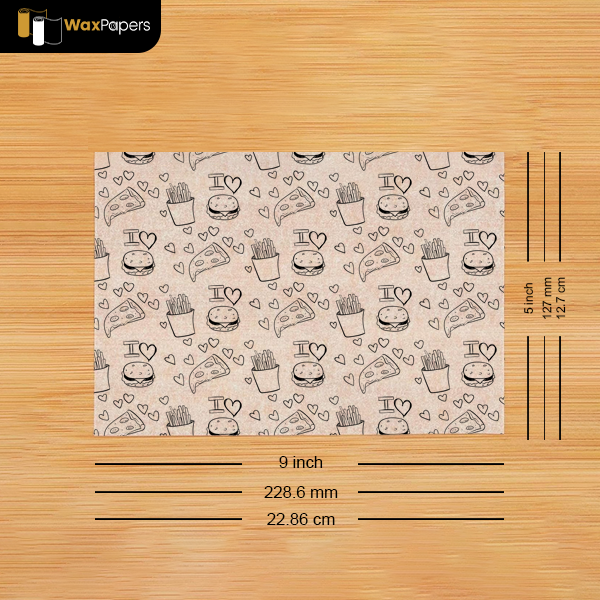

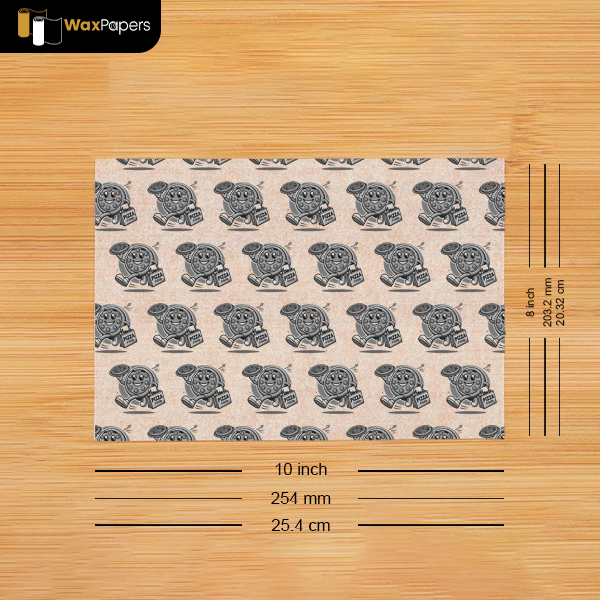

| 4" x 4" | 5" x 5" | 6" x 5" | 6" x 6" |

| 7" x 5" | 7" x 7" | 8" x 5" | 8" x 6" |

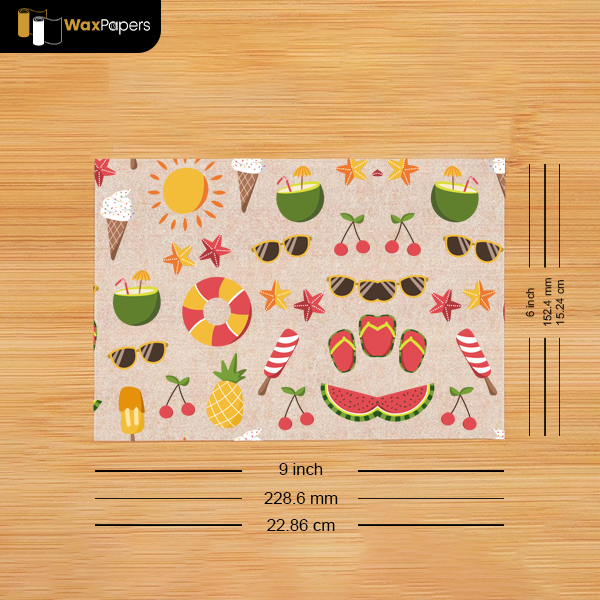

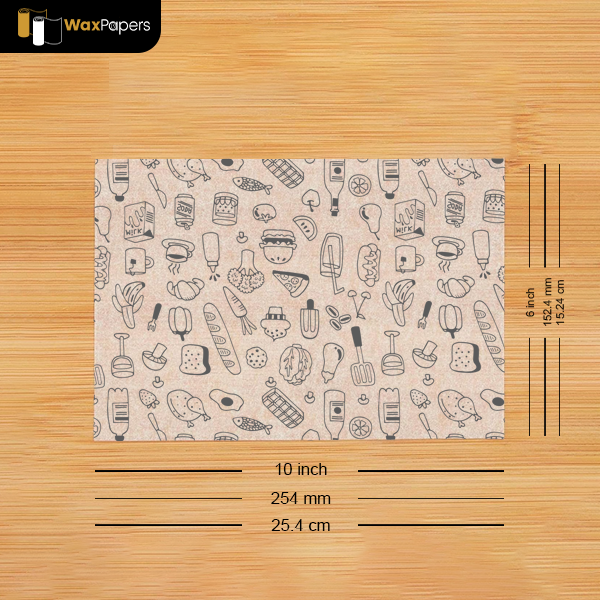

| 8" x 8" | 8.5" x 11" | 9" x 5" | 9" x 6" |

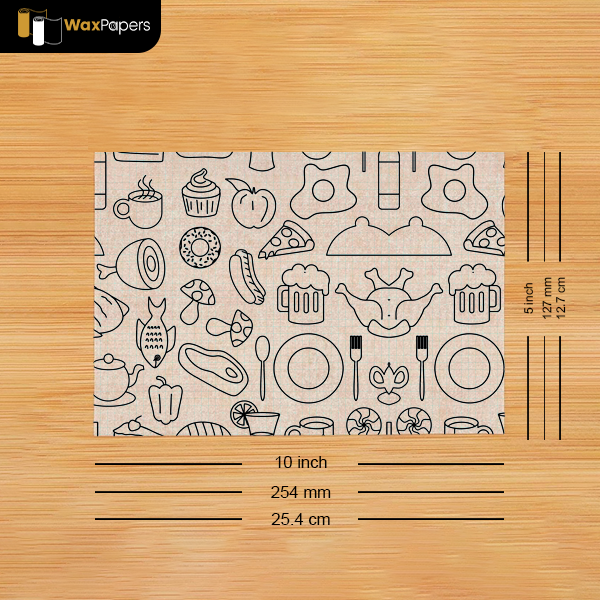

| 9" x 9" | 10" x 5" | 10" x 6" | 10" x 8" |

| 10" x 10" | 10.75" x 10" | 12" x 6" | 12" x 8" |

| 12" x 9" | 12" x 10" | 12" x 12" | 13" x 6" |

| 13" x 9" | 13" x 10" | 13" x 13" | 14" x 12" |

| 15" x 9" | 15" x 10.75" | 15" x 12" | 15" x 13" |

| 16" x 12" | 17" x 11" | 18" x 10" | 18" x 12" |

| 18" x 13" | 20" x 10" | 20" x 12" | 20" x 13" |

| 20" x 15" | 20" x 18" | 20" x 20" | 20" x 25" |

| 20" x 28" |

Product

Dimensions

Frequently Asked Questions

Yes, the glassine is acid-free. Glassine won’t adhere to painted surfaces. It is a clear, acid-free, unstored glassine. It is perfect for wrapping paintings for shipment and interleaving matted prints.

Glassine achieves the highest possible level of smoothness and thinness. It is eventually unstable even if it is PH neutral since it is not always lignin-free. The standard shelf life of glassine paper is three to five years.

We provide a minimum turnaround time and complete your order within 4-6 days. We always provide complete customer satisfaction by delivering their order on time.

Yes, our company provides free sampling like prototypes and 3D samples to give a clear-cut view of your products. We also offer a physical sampling at the request of the client and we charge a little cost for it.

Yes, you can. We offer wholesale boxes at affordable prices. Our company always meets the client’s budget requirements.

We offer 100 minimum order level quantities for our clients. We also offer a 50% discount to our clients who place the orders in bulk.

The minimum order quantity of glassine rolls is 10.

There is no consultation fee for designers. You can simply fill in the quote and book a free consultation.

No, we use sustainable and food-grade paper that does not cause any kind of health hazard to the customers.

You can get a paper roll of 3 meters maximum. For sheets, there are several options based on customer preferences.

Product

Highlights

Custom Wax Paper

Greaseproof Paper

Welcome to the ultimate destination for Custom Wax Paper and Greaseproof Paper – the perfect way to add a unique touch to your restaurant's food packaging.

Designed specifically for restaurants, our printed paper liners brings unparalleled quality and functionality with a touch of personality to your brand. Enjoy our exclusive offer and order your custom wax paper now!

Get a Quote